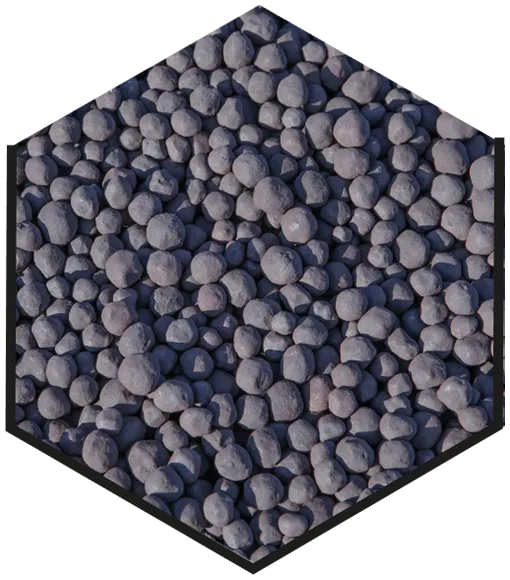

This product is extracted and produced from the steel industry. This product is made from the combination of several rich raw materials and various types of rocks, including magnetite and hematite, which are converted into powder during the extraction and market entry phase. That is why the name “concentration” was chosen for this powdered product, which is mostly used to increase the grade and value of iron ores.

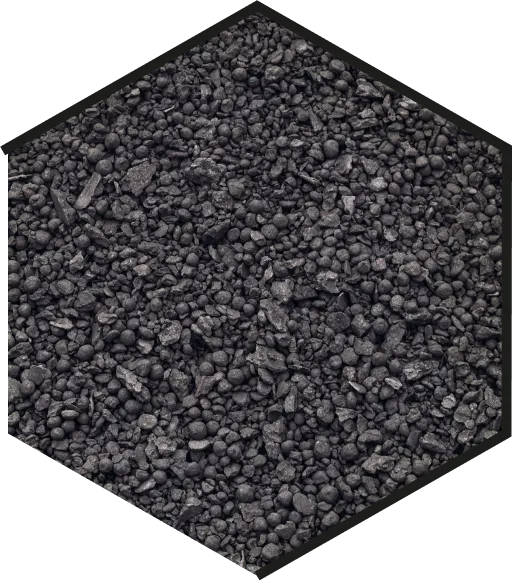

This product has a dark black color and is used as a raw material for the production of products such as iron pellets. Among the reasons that have made this product highly valuable in the industry are factors such as the absence of environmentally harmful substances, non-flammability, rapid production, and cost-effectiveness.

Considering that a part of the economic income is dependent on the production of this material, and the demand for this material is increasing, a product like iron concentrate has been able to meet the needs of applicants and the iron market completely and at an affordable price by increasing the quality of iron ores.